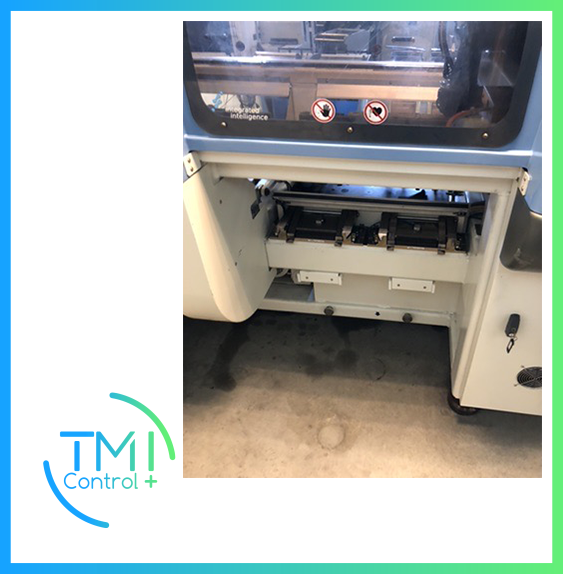

EUROPLACER - Machine de report IINEO 2

EUROPLACER - iineo 2T - Automatic SMT Placement System

Refurbished equipement

- Vintage : 2013 (29 897 hours)

- Dimensions (L x l x H) : 2915 x 1700 x 1660 mm

- Standard in line conveyor

- PCB dimensions (L x l) : 500 x 460 mm

- Manual width adjustment conveyor

- Dual X - Y placement gantry on linear motor

- Two high speed turret placement head with global Z and Theta axis movement and equipped :

. 1 board CCD camera : PCB fiducial / Self teach CCD digital camera

. 1 component CCD "on the fly" hi-resolution camera (3DPS)

- 2 turrets 8 nozzles / Max components height : 31 mm

- Component range : 01005 to 50 x 50 mm

- 4 x 40 positions "smart" noozle tool bank (without nozzle)

- 6 x Trolley clamp adaptor for gun trolley, Trolleys or Jedec plate loader.

- 2 x fixed feeder position (for NT feeders, Label Feeder, Stick distributor).

- Integrated PC computer and flat screen monitor

- Windows 7 operating system

- Europlacer licence RC-5.15

- Technical documentation, manuals and diagrams on PDF files on the PC.

- Complies with CE machine directive

- Power supply : 400 Volts (3P+N+T)

- Air supply : 6 bar

- Color : RAL 9002

machine_contact

Contact us

Refurbished

Thorough check-up of the equipment before complete refurbishment in our workshop, carried out by a highly skilled team, eventually tested before release & shippment

Installed in your factory

Material release, setting on the SMT line and start-up of the equipment carried out by a skilled & experienced engineer. We can also assist you during the start-up of production.

Training included

User training, programming & maintenance training ensured by a skilled engineer

Guarantee

All products are guaranteed to ensure the continuity of production, similar to what you would expect from a brand new equipment

Financing

We offer a quick turnkey solution which will safeguard your capex capability for other invests

Maintenance contract

Preventive annual maintenance to guarantee your production continuity and significantly decrease the maintenance cost of your SMT production line